Stainless steel expanded metal mesh is made of a single solid sheet of compressed and stretched material. The expanded metal grating is useful for heavyweight custom parts washing applications, as well as providing open space for air flow and drainage.

There are two distinct varieties of expanded stainless steel mesh used for baskets: standard and flattened. The term “standard expanded metal” refers to the metal as it comes out of the expanding machine. On the other hand, flattened expanded metal is what happens when standard expanded metal is put through a cold rolling steel mill to flatten the expanded stainless steel mesh.

Expanded Metal is manufactured in 2 ways - Flattened and Raised. Raised Expanded metal, also referred to as standard expanded metal, is the format of steel, aluminum or stainless steel after it has been put through the expanding press. The shearing and stretching of the expanding process creates strands and bonds that are set at a uniform angle to the plane on the sheet. This adds strength and rigidity to the material, while providing a directional skid-resistant surface. Flattened Expanded metal is manufactured by passing the raised expanded sheet through a cold roll flattening press. This flattens the strands and bonds surface, reducing the thickness (gauge) and elongating the pattern. Expanded Grating is milled in a similar manner to expanded metal. The difference is in the thickness (gauge) of the strand. Expanded grating, because of the thicker strand gauge, has better load bearing characteristics and therefore lends itself to a wider variety of applications.

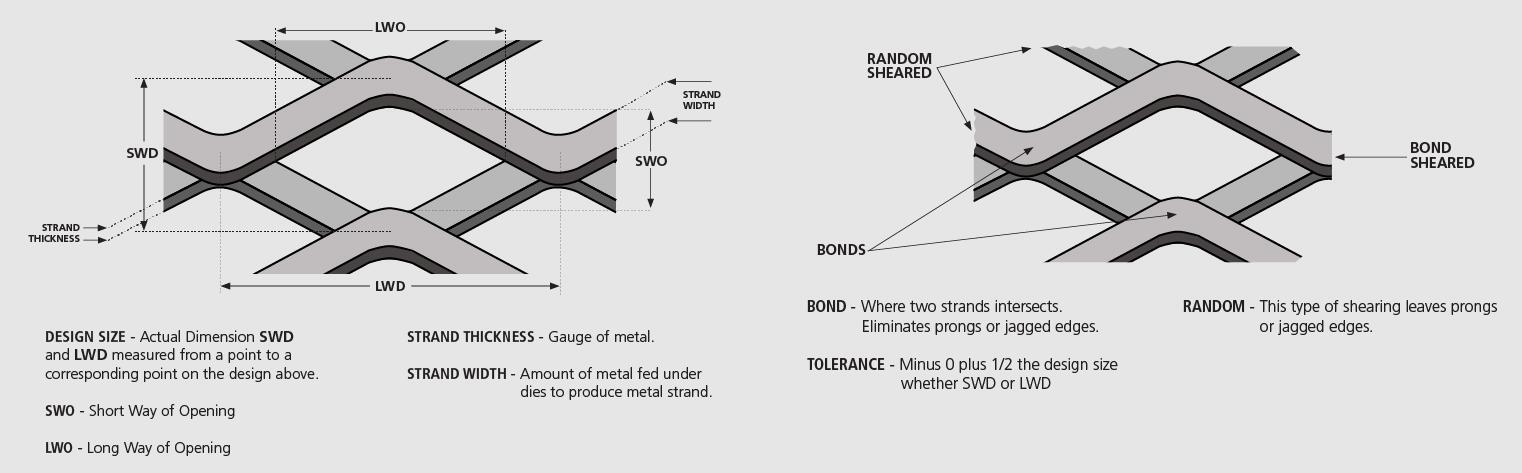

Here is a brief list of useful stainless steel expanded metal terms:

✴Strands. This is the term for the solid metal portions of the expanded metal grating. In the diagram at the top of the article, the strands are 0.107" wide.

✴Bonds. This is the term for intersections of strands.

✴Short Way of Design (SWD). The distance between the centers of bond strands in the mesh when measured along the short diamond diagonal. To illustrate this, in a diamond pattern shape like “<>,” the SWD would be measured from top to bottom. In the diagram above, the SWD would be approximately 0.372" (0.265" SWO plus 0.107" of strand thickness).

✴Long Way of Design (LWD). The distance between the centers of bond strands in the mesh when measured along the long diamond diagonal. In a diamond pattern shape “<>,” LWD would be measured from right to left. In the diagram above, the LWD would be approximately 1.107" (1" LWO plus 0.107" of strand thickness).

✴Short Way of Opening (SWO). The distance between the inside edges between bonds when measured across the short diamond diagonal. The difference from SWD is that SWO measures open space, while SWD measures the space from the center of one bond strand to the next. In the diagram above, the SWO would be 0.265".

✴Long Way of Opening (LWO). The distance between the inside edges between bond strands when measured across the long diamond diagonal. Like with SWO, the difference between LWO and LWD is that LWO measures open space only, while LWD measures to the center of a bond strand. In the diagram above, the LWO would be 1".

✴Strand Thickness. A measure of the thickness of a strand of expanded metal.

✴Strand Width. How wide a strand of expanded metal is.

When measuring expanded stainless steel metal mesh, it’s important to consider the overall size of the metal plate after it is expanded, its long and short way of opening, and its strand thickness and width. This is because each of these factors will affect the basket’s performance.

For example, larger LWOs and SWOs mean the holes in the mesh are larger, which improves air flow for the expanded stainless steel mesh basket. On the other hand, thicker and wider strands tend to be stronger than thinner strands.

Comparing LWO and SWO against LWD and SWD helps to confirm the width of metal strands and overall open space of the mesh. For example, if the SWD and LWD of the mesh is 0.5” and 1”, and the SWO and LWO is 0.4” and 0.8”, then the width of the bond should be approximately 0.2” x 0.4”. This would provide a strand width of 0.1”. This would also create an open space of roughly 0.5 inches squared for each opening in the mesh.

As noted above, stainless steel expanded metal mesh has a wide variety of applications across several industries. Some applications companies have used these incredibly tough and resilient baskets include:

▲Shot Peening Parts

Shot peening is the process of shooting parts with small particles of glass, metal, or ceramic to alter the part’s surface characteristics. Obviously, this kind of high-impact process is going to be incredibly stressful on the baskets holding the parts through the shot peening process.

Using expanded metal for the basket allows the particulates used in the shot peening process to reach the parts being modified, but gives the basket itself enough strength to survive repeated exposure to the process—unlike a steel wire basket, where a single wire might break from the impact.

▲Shot Blasting Parts

Shot blasting is a similar process to shot peening, but may use smaller particulates to not only change the surface properties of a part, but also to strip it clean of contaminants and/or to polish it. Here, grade 316 expanded metal baskets are useful because of their incredible durability, which makes them able to survive prolonged use in this high-stress application.

▲Part Organization/Stacking

Heavy-duty grade 316 stainless steel expanded metal baskets are incredibly durable compared to their wire mesh counterparts. When created with a nesting or stacking design in mind, fully-loaded expanded metal baskets can be stacked to save space on the factory floor.

Many companies use this ability to stack baskets to help organize their finished parts as they await delivery or to dry off between processes.

▲Degreasing Components and Brackets

Many vapor degreasing processes use incredibly caustic solutions that are heated to the boiling point to break up stubborn contaminants, such as machine oil/grease, and liquefy them so they can drain away from the part being degreased.

Grade 316 stainless steel can withstand exposure to the caustic solutions used in vapor degreasing and many other parts cleaning processes—making it the ideal material for this particular application.

▲Fire Safes for Warehouses

Some users of expanded metal baskets have used them as a kind of fire safe to protect delicate parts or papers in case of a warehouse or factory fire. When designed for this purpose, the expanded metal baskets are usually built in layers, featuring an open outer frame to keep heavy debris from impacting the sealed containers held within.

With its high melting point and a layer of insulation between the expanded metal frame and the sealed container held within, these baskets can be surprisingly effective at protecting delicate items from the fury of a blaze and the incidental impacts that may occur.

▲Storage of Heavy Metal Parts

Several automotive parts manufacturers and companies in the aerospace industry have used stainless steel expanded metal baskets to hold their heaviest metal components as they were moved from one process to the next.

Why use grade 316 stainless steel for parts storage? In these cases, the baskets were doing more than just holding the parts—most steel alloys would have enough tensile strength for that. Instead, the baskets would often need to be able to withstand exposure to chloride-based solutions or salt-enriched air. Here, the superior chemical resistance of grade 316 stainless was needed to ensure the long-term viability of the basket.

Our steel plate mesh is a durable material often used for machine guarding, trailer floors, filters, separators, baskets, awnings, storage bins, rack floors, fencing and walkway floors. Galvanized, aluminum and stainless steel sheet metal mesh is not easily damaged by environmental factors such as water damage and corrosion, making it the perfect choice for outdoor applications. Expanded metal can provide greater traction through its exposed edges, which leads to its use for fashion shows or drainage covers.

Although expanded metal is a strong product, it is a very light material compared to other materials, which makes it an easy-to-install option for security applications. It is also very conductive, which means it can conduct heat and electricity due to the fact that the original sheet has no welds or fractures.

Copyright © HEBEI METAL MESH CORP All Rights Reserved Sitemap