Cutting expanded metal can be more difficult than cutting other types of metal — it takes the right equipment, correct technique and a little extra patience. With the right information, tools and method, however, a trained professional can cut expanded metal precisely without damaging the equipment or materials.

The first step toward correctly cutting expanded metal is finding the right tools that will aid the process. The following equipment is crucial:

· Cutting tool: Consider the size and nature of the expanded metal you need to cut. Then, choose a grinder, drill, saw or laser tool.

· Measuring device: Either a tape measure or a ruler will work fine.

· Clamps: These tools hold the metal in place while you cut.

· Protective gear: It’s crucial that you stay safe during the process, which includes safety glasses, a protective apron or cloth, gloves and safety boots.

You’ll find several quality expanded metals on the market, each one designed for a particular application. Knowing which one you’ll need to cut influences the process. Consider the following:

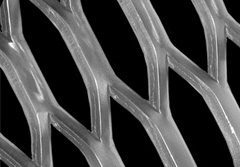

· Standard expandable metal: Standard, also called regular expanded metal is created with a process of simultaneously cutting and stretching solid metal, this makes it look like the metal is in a diamond pattern. Standard expanded has a raised surface that is good for many purposes like security fencing, wall cladding, and much more.

· Flattened expandable metal: Flattened expanded metal is just how it sounds, flat. It is standard expanded metal that goes through a cold rolling process that creates a more smooth and level surface. Flattened expanded is useful for bridge railings, wall panels, ceiling panels and more.

· Expanded metal grating: Expanded metal grating is a heavy-gauge, durable grating that is made with low carbon steel plates. This expanded grating can be turned sideways for catwalk grating so the surface is rough and grips work boots.

The type of metal used in each of these designs can vary from aluminum and copper to steel and several others. Physical properties and strength are different between designs and metal types, so you’ll rely on this information to choose adequate cutting equipment.

Before starting, make sure you have all your tools ready and safety gear in place so you can focus on cutting without feeling unsafe or becoming distracted. Make sure your tools are working correctly, whether that means tightening a grinding disk or checking the function of a laser cutter. Then, follow these steps:

1. Figure out what shearing is necessary: Expanded metal shearing is a term known throughout the industry to convey the type of ends you would like cut.

2. Make accurate measurements: Even a small deviation from the right measurement could waste pieces of metal and cost unnecessary money. Make permanent marks on the metal so you know exactly where you’ll need to cut.

3. Clamp the expanded metal tightly in place: You’ll need to exert force with your drill, saw or other tool, which could cause the metal to move sideways and produce waste if you don’t clamp correctly.

4. Place the portion to be cut on a raised surface for convenience: This will keep you from cutting the working surface, but make sure it’s not a rock or something too hard that could damage your tool.

5. Start in the right place: If you’re cutting a small piece of expanded metal from a larger sheet, start from one edge. You have a higher chance of creating waste if you start at a point away from the edges.

6. Hold correctly: Hold your tool firmly, and do not apply too much force, as doing so will move it from your marked line. Keep a steady hand until you reach the final mark, and remember that the tool can move faster on expanded metal due to the gaps, so be careful.

7. Finish edges with U-edging: U-edging is attached to the ends of expanded metal and other types of metal that can be course after being cut.

If you’re looking for quality expanded metal fabrication, we can help you. We’ll work with you to come up with the perfect material and design for your unique application. Contact us today for more information.

Copyright © HEBEI METAL MESH CORP All Rights Reserved Sitemap