Quickly name the most widely used and cost effective scientific instrument in your lab. A few possibilities come to mind, but our argument is for the common test sieve. To a large extent, there is no simpler, more efficient, or more cost-effective way to analyze particle size in a variety of materials than test sieves.

Precision instruments that perform more accurate measurements have a place in particle analysis. However, when the focus is on basic particle size and classification, the benefits gained do not always offset the effort and cost involved. These instruments also confound the traditional interpretation of cumulative historical data if the results do not correlate with the mesh sieve test.

Etched Perforated Plate

Sieving is an ancient science based on simple principles deeply rooted in materials testing laboratories as a standard method for measuring particle size. Since the process assumes that each particle is a perfect sphere, there has always been a question of the absolute accuracy of determining particle size by sieving.

It has been practiced on many different materials for a long time, so much so that variations in shape are accepted for construction materials, chemicals, food, pharmaceutical granular materials, powders, and many other products. Each of these disciplines has developed published test methods for their materials. astm has also published their own. Handbook 32 - Test Sieving Methods, which is a comprehensive guide to test sieving methods and analytical procedures.

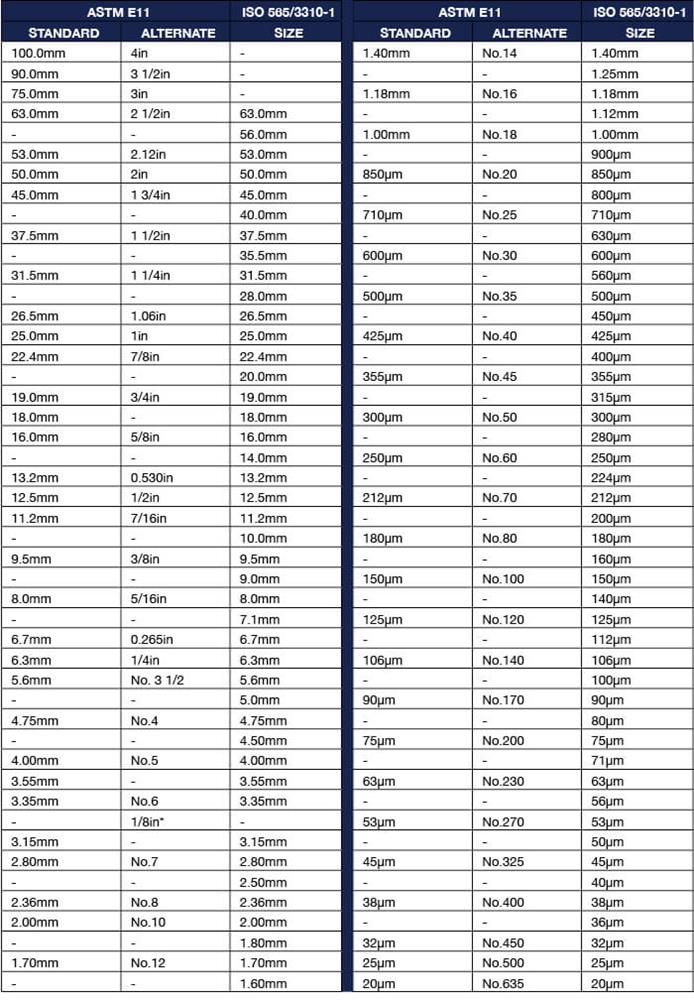

ASTM E11 and ISO 3310-1 standards list specifications for woven wire sieves. Particles from 150 mm (6 in.) to 5 µm (0.0002 in.) can be effectively sieved using the appropriate test method.

perforated sieves

So, while test sieves are simple, they are still scientific instruments and should be carefully selected, used and maintained. Let's take a closer look at the mesh sieve itself, sieve construction, materials and design options.

The separation media for most sieves is metal or synthetic woven wire mesh. Perforated sheet metal is another separation media, and electroformed wire mesh is a flat metal plate with precision openings.

For conventional ASTM/ISO test sieves with wire mesh, opening sizes range from 125 mm to 20 microns (5.0 inches to No. 635). It is up to the industry standard test method or sometimes the operator to determine which opening size is appropriate for a particular sample.

Some test methods specify the desired opening or the sieve can be selected to provide useful information about the grading profile. Usually used every second or fourth size in a series to give a uniform indication of distribution. Inserting intermediate sieves in a stack can prevent overloading or better define the size range.

Wire screens are manufactured on large industrial looms using metal wires in various weaving patterns. The wire mesh is cut to size and mounted on the frame by welding or using a high strength epoxy adhesive. Proper tensioning ensures uniform openings and prevents the finer wire mesh from stretching and sagging during use, increasing the screen's life.

● In the past, brass wire mesh was favored for screening because of its ductility and lower cost. It is still sometimes required for certain hazardous materials because of their spark resistance. Brass wire mesh is available in sizes ranging from 2.36 mm to 45 microns (8 gauge to 325 gauge).

● Stainless steel wire mesh is more durable, less likely to contaminate sensitive materials during processing, and better able to hold its specified openings. It also costs less than brass today, and modern tools make it easier to weave, form and install. Stainless steel mesh is available in a full range of ASTM/ISO sizes from 125mm to 20µm (5.0in to No.635).

1. Non-metallic wire mesh woven from polyester or nylon filaments can be used in non-metallic screens for unique applications or as disposable cloth for two-part screen frames. This synthetic mesh is suitable for applications where metal mesh is not allowed or may be contaminated. The opening size is equivalent to many ASTM/ISO sizes, but the synthetic cloth does not meet the E11 or 3310-1 requirements for material type or wire diameter.

2. Perforated sheet is a precision stamped steel sheet that meets the requirements of ASTM E323. Perforated plates are commonly used for sieve analysis of coal (ASTM D4749) or ores, coke, wood chips and other specialty materials. Perforated plate openings range from 3.18 to 100 mm (1/8 to 4.0 in.).

3. The electroformed mesh is square in size, accurate in height and very consistent. Tolerances are held to ±1 to 2µm for openings from 150µm to 5µm. This sieving media is expensive and the fine mesh is fragile, but it is the best choice for applications where precise sizing of fine materials is critical. The nickel used to make electroformed screens is electrodeposited on the flat stainless steel mesh surface.ASTM E161 and ISO 3310-3 specifications list the tolerances for these screens, which are measured separately and are available with documentation of compliance.

Just as the opening size must be selected based on material dimensions, the frame type is considered when selecting a sieve.

The sieve frame provides a stable platform for proper installation and tensioning of the sieve and confines the sample material during the mixing process. Circular test sieves include a skirt that can be nested with other sieves to form a multi-screen stack for sieve shakers.

Traditional circular test sieves are available in a variety of frame configurations, and choosing the right configuration can have an impact on each application. A previous blog post detailed unique frames such as screen trays for test screens, wet wash screens and other screens for less common applications.

The frame diameter is a critical step in matching the sieve size to the sample volume. Large samples contained in frames that are too small can result in poor separation when particles cannot find the sieve holes. The size fraction is not completely separated. The rule of thumb for matching frame diameter to sample volume is that no more than one or two layers of material should remain on the sieve after separation is complete.

Choosing a larger sieve allows the use of larger, more representative samples and promotes better fractionation. Conversely, smaller sieve frames allow for better control of small samples of fine powders and are easier to clean for complete particle recovery. Some test methods recommend testing sieves with at least five full holes, so any sieve has a limit on the upper size of the mesh.

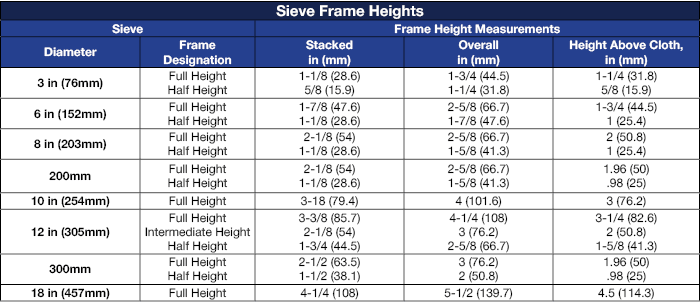

The table below lists the frame diameters and other key dimensions for ASTM E11 and ISO 3310 test sieves.

The frame height option allows you to maximize testing efficiency when separating multiple fractions on a sieve machine. Half-height sieves allow a greater number of sieves to be stacked in the same vertical space. Keep in mind that each particle must have enough room to rise from the screen surface, reorient, and then return to the screen in a different position during the mixing process, so coarse particles still require a full-height screen.

The choice of frame material is usually a practical matter of price, long-term durability and application requirements.

● Stainless steel is the best choice for most applications because of its low cost, long life, low sample contamination rate and corrosion resistance.

● Brass has recently become more expensive, but it is a traditional choice and can still be used to test certain materials that may produce sparks.

● Combination frames are made of stainless steel mesh with brass frame hoops and stainless steel skirts for added durability.

● Acrylic frames offer advantages for smaller sieves. The material is easily machined for precise nesting fits and allows visual monitoring of the sample during mixing. A high-strength adhesive holds the sieve firmly in place on the frame.

Backing fabric is an option designed to increase the life of the primary sieve and offset the effects of frequent use and overload. Coarser, stronger 30-gauge (600µm) wire mesh is factory installed as a reinforcement under a 70-gauge (212µm) or finer primary screen, especially for wet wash screens.

We hope this blog post has helped you understand the form and function of test sieves. Please contact us with questions about your screen project.

Copyright © HEBEI METAL MESH CORP All Rights Reserved Sitemap