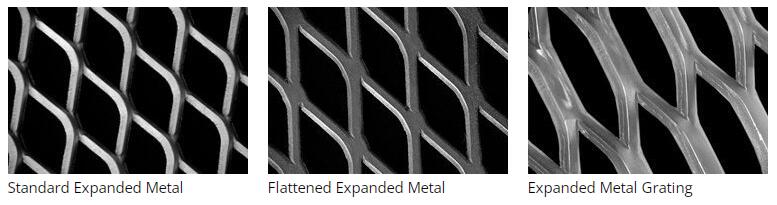

Flattened expanded metal is simply standard expanded metal that goes through the “cold rolling” technique. Cold rolling is the manufacturing process in a steel mill that involves flattening the sheet by passing it through flattening rollers. This takes all the ridges out, therefore, produces a flat and level surface. This process stretches the pattern even further to produce a thinner, flatter, and wider/longer metal sheet.

Flattened expanded metal offers many of the advantages of standard expanded metal, such as versatility, a wide variety of opening sizes, low maintenance and cost-effectiveness. Since cold rolled expanded metal is lighter than standard expanded metal, it suits applications that require a nimbler and more agile product that still offers the necessary strength and durability.

Note regarding flattened; sizes will vary depending on whether the cylinder is passed along the design’s short path (SWD, narrow direction of diamond pattern) or long design path (LWD, wider, longer direction). diamond pattern).

Flattened metal uses include:

· Infill panels

· Fencing

· Walkway railings

· Security partitions

· Security walls and doors

· Grilles and vents

· Ceiling tiles

· Shelving

Benefits:

· Martial weight is less than raised

· Allows air, liquid, and light to pass through

· Architectural benefits due to aesthetic appearance

Standard expanded metal is sometimes referred to as raised metal because of its more three-dimensional look. This angled, or bumpy property adds strength and rigidity.

Raised metal uses include:

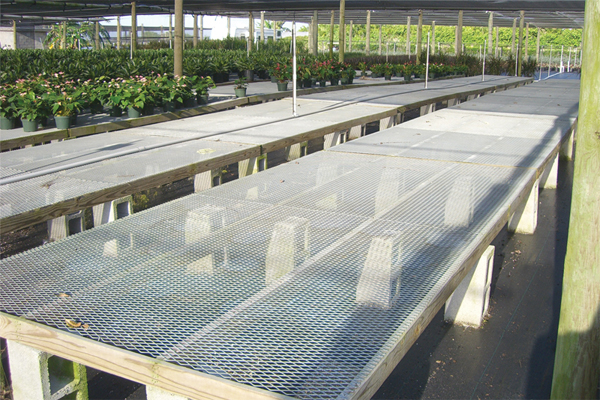

· Platforms and walkways

· Metal gate protection panels

· Racks and shelving

· Strainers

· Security walls and doors

· Speaker grilles

· Wind and machine guards

· EMI/RFI shielding

· Fluid and air filters

Benefits:

· Distributes the load of the metal to the supporting frames, therefore increasing structural strength

· Security aspects

· Can provide light reduction

· Allows air, liquid, and light to pass through

· Exceptional gripping properties

Another, more heavyweight version is expanded metal grating. This metal is thicker and can be turned sideways for extreme nonslip walking surfaces such as catwalks.

Expanded metal grating is made of a single solid sheet of material so it tends to be stronger and requires less welding.

Some of our metalwork capabilities include cutting, punching, shearing, sawing, cut-outs, welding, drilling, and slitting. We are a one-stop-metal-shop. Contractors, end-users and metal suppliers all use our services to save on costs, overcome their project challenges and customize the expanded metal products they purchase from us.

Copyright © HEBEI METAL MESH CORP All Rights Reserved Sitemap