The wide variety of materials, classifications and applications makes it difficult to determine which type of metal grating you should use for your project. To help, we've provided detailed information about the different types of metal gratings, including how they are manufactured, their properties and common applications.

In the metals industry, "grating" can refer to several different types of metal products. Each type has its own unique set of properties that make it more (or less) suitable for individual applications. For example, street drains will use a form of bar grating, while sidewalks often require a more secure extension grating or grip post. Regardless of their specific application, metal grating as a whole can provide proper drainage, ventilation and safety measures for a variety of industries.

Do you need metal grating for your project?HEBEI METAL MESH CORP has the products you need. Check out our list of wire mesh products.

Metal grating varies greatly in material and function. Depending on the application, different types of metals and production patterns are used to ensure successful and safe operating conditions. These factors depend on parameters such as strength, size, location and use.

Wire Mesh

Wire mesh, which can also be referred to as wire fabric or cloth, is a form of metal grating that consists of parallel rows and crossed columns of metal. It is easy to install, very durable, and can be used in a variety of different industries. Because it can be made of a variety of different materials and metals and can meet an almost unlimited number of specifications, it is very versatile and can be used for many different applications.

Wire mesh is commonly used in industrial and commercial applications. A few of its uses include.

▴ Separation and filtration

▴ Ventilation

▴ Material reinforcement

▴ Screening and fencing

▴ Security

▴ Art

The two most common types of wire mesh are: welded wire mesh or woven wire mesh. As the name implies, welded wire mesh has intersecting rows and columns of parallel lines that are welded together at the intersection, while woven wire mesh has a series of intersecting lines woven above and below the vertical lines to form a stable sheet.

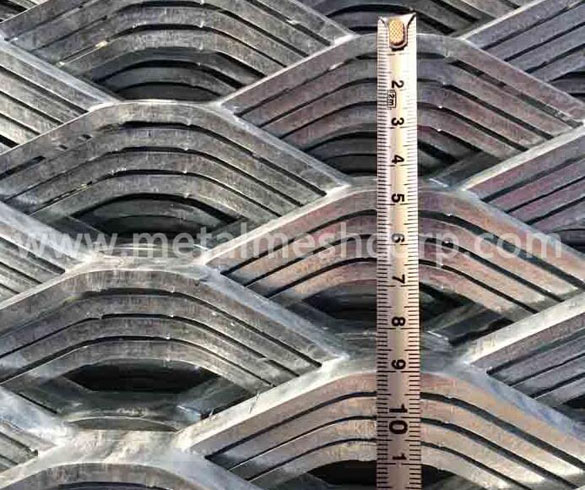

Expanded Metal Grating

Steel plate grating is made by making slits in the sheet metal and then stretching (expanding) the sheet metal to create a diamond pattern. The sheets can then be cut to size and flattened. Many different types of metals can be expanded, such as stainless steel, carbon steel, aluminum, etc.

The expansion process is very economical because it produces no waste and the sheet will retain its structural strength since no holes are punched in the material. Typical uses for expanded metal grating include steps, flooring, fencing and security applications.

Perforated Metal

Perforated metal, also known as perforated panels, perforated sheets or perforated screens, is a form of metal grating made from stamped or punched metal sheets to create a specific hole pattern. It is typically made of stainless steel, carbon steel or aluminum and is made by several different metal manufacturing processes. These include rotary pin perforation, die and press perforation, and laser perforation.

Perforated metals are used in a variety of industries and have many applications, including:

✱ Noise reduction

✱ Filtration and centrifugation

✱ Ventilation

✱ Chemical purification

✱Screening

✱Construction material development

During the perforation process, the removed metal is recycled, improving sustainability and reducing overall metal use. This reduction in material usually means reduced weight and lower transportation costs.

Bar Grating

Bar grating is made up of parallel bars joined together with vertical bars. Bars are most often joined by welding, however, there are other methods of joining bars together. Alternatives include riveting, tight engagement, compression locking, etc. The most economical method of connection depends on the material used and the thickness of the reinforcement.

Bar grating can be made of many different materials, but is most commonly made of steel or aluminum. It has a very high strength-to-weight ratio and a large amount of open space, making it a widely used choice for industrial flooring. However, it can also be used for applications such as fire escapes, street drains and bridges.

Safety Grating

Safety grating is a common form of metal grating used for walking surfaces. It is designed to help increase traction and prevent the risk of slips or falls. It is usually made of small diamond-shaped protrusions that provide greater traction. It also has many open surfaces that provide ample drainage and air flow. The most common form of safety grille helps increase grip when walking across. This is accomplished by serrating the diamond edges created after cold-stamping the sheet metal.

Many different types of metals are used to make grips, including steel and aluminum. Once it has been stamped and serrated, the sheet metal is then coated with a material that minimizes slippage. Because of its high traction, it is used for sidewalks, stairs and other walking platforms.

Copyright © HEBEI METAL MESH CORP All Rights Reserved Sitemap